As you take a sip from your next can of beer, you can thank Bill Coors and a team of more than 100 in Golden, Colo., for its fresh taste.

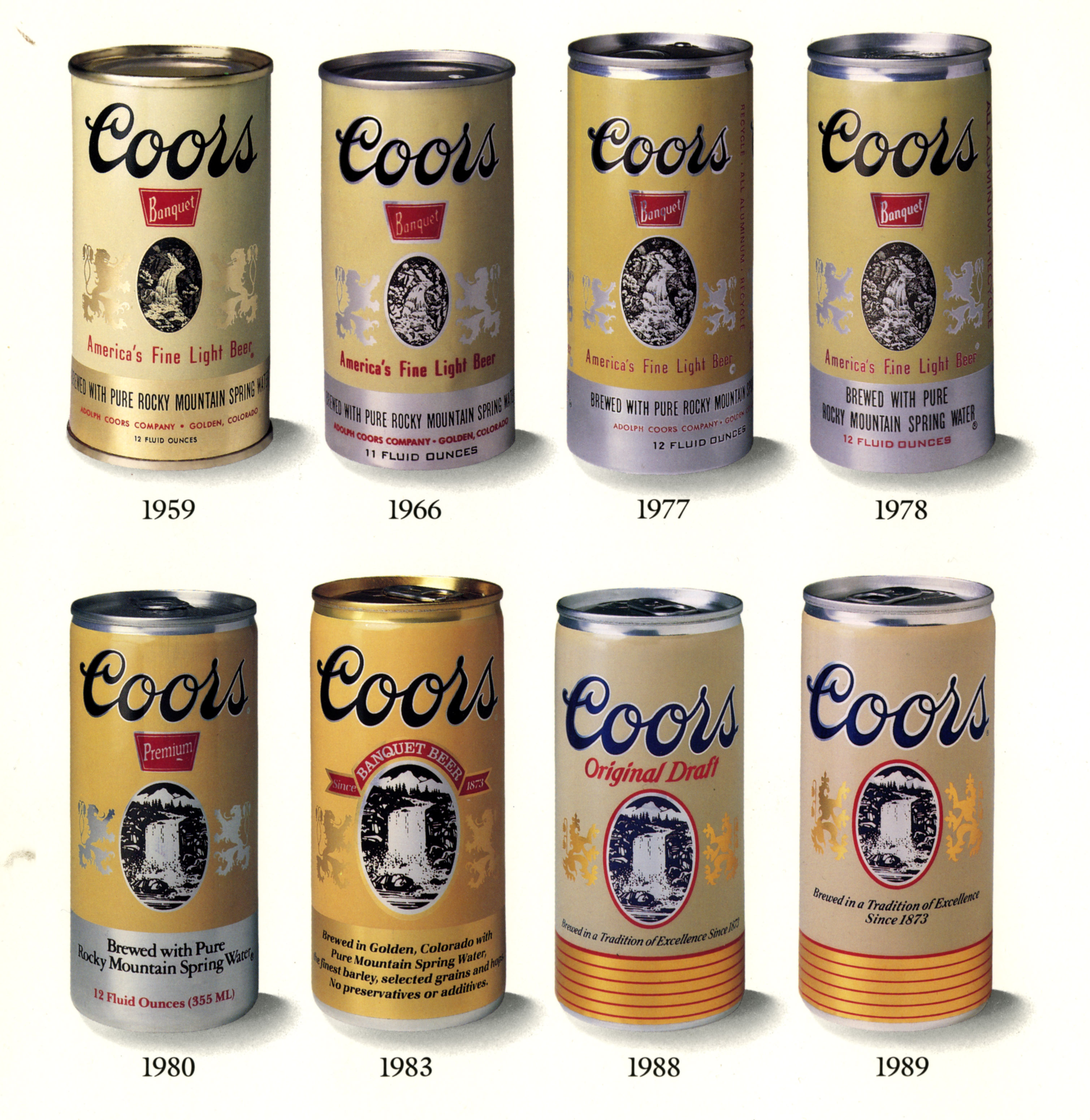

Sixty years ago today, on Jan. 22, 1959, the two-piece recyclable aluminum can designed by Coors made its debut with a 7-ounce Coors Banquet, a move that revolutionized the beverage container industry.

Pioneered by the late former Adolph Coors Co. chairman, the aluminum can was the product of years of research and $10 million worth of trial and error. Coors undertook the initiative with two goals in mind: Clearing the landscape of throwaway steel cans and colder, better-tasting beer.

Inspired by European technologies and other discussions, Bill Coors and others in the mid-1950s researched the manufacturing processes and started amassing equipment. Within five years, those first Banquets began rolling off the line.

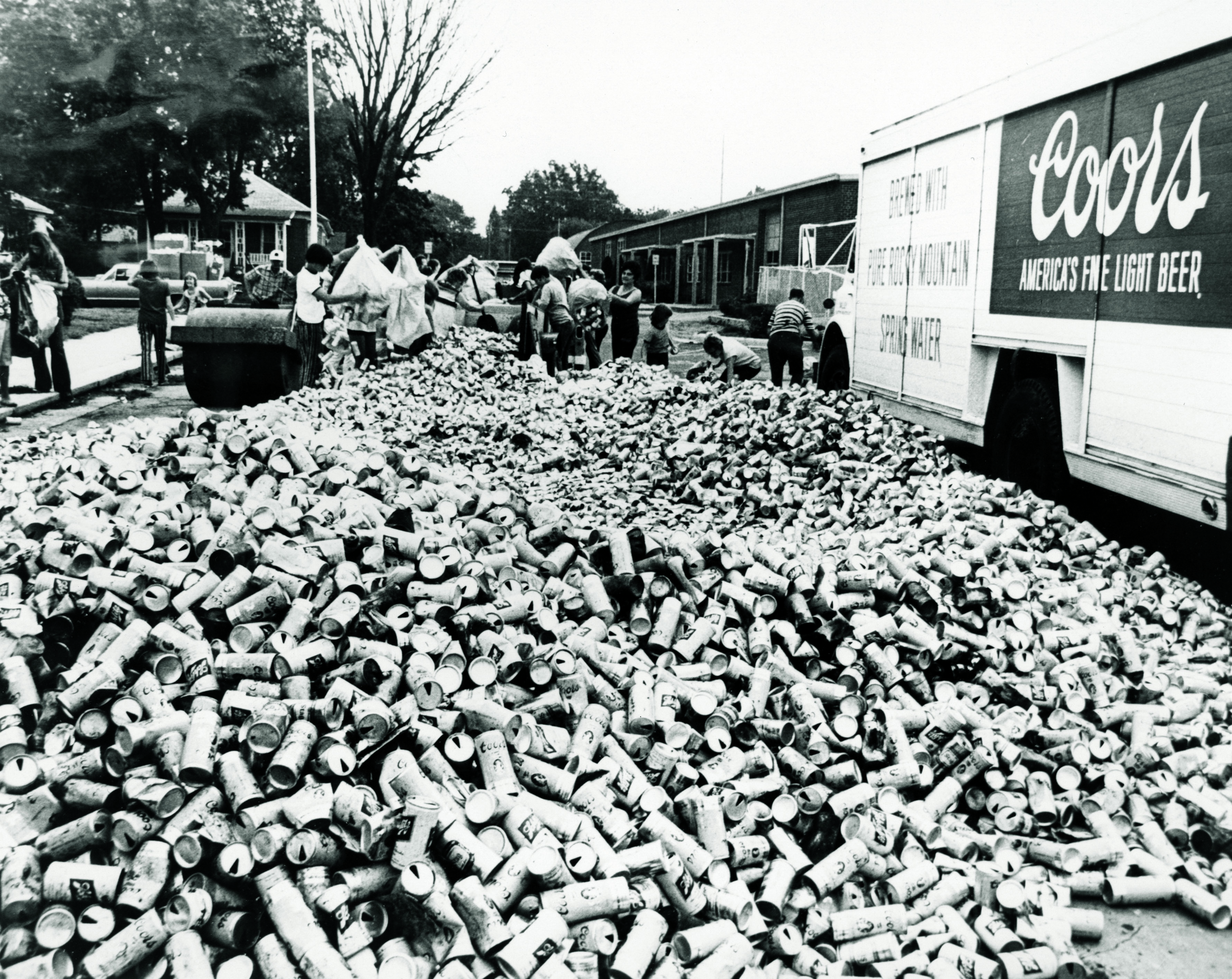

The company concurrently spearheaded a recycling effort, which later became “Cash for Cans,” a program that would lay the groundwork for nationwide efforts that continue today.

Because of his passion for the environment, Bill Coors wanted to make sure other beverage makers would join Coors' efforts to start a recycling revolution. His big bet paid off. After years of advances, that aluminum can holding your beer has the potential to be born again in fewer than 30 days.

MillerCoors continues Bill Coors’ legacy today through a series of sustainability programs.

Here’s a look at 10 fun facts about the recyclable aluminum can as we celebrate its 60th anniversary.

- An environmental and taste issue inspired the aluminum can. In the 1950s, cans were made of steel and thrown away with abandon. Everywhere. The steel cans not only littered the environment and became a health hazard, but they lent a metallic taste to the beer. Bill Coors sought a solution for both issues.

- More than 100 people were involved in its development. Bill Coors recruited engineers from Coors Porcelain Co. to start brainstorming the manufacture of an aluminum beverage can. Over the course of the project, an estimated 113 people helped with the development and manufacturing of the aluminum can.

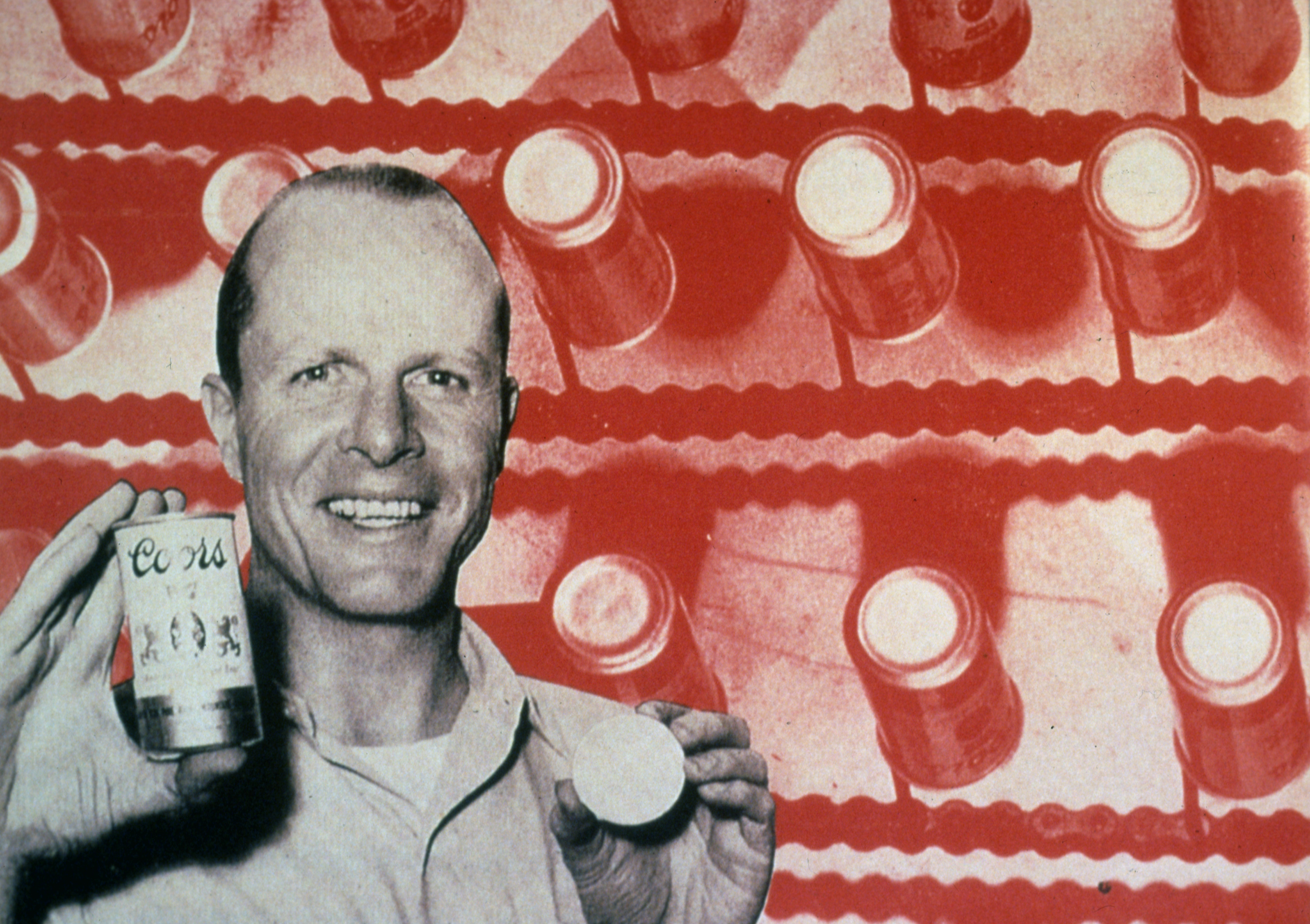

- The industry was not on board. The United States Brewers Association, the soda industry and the beverage container industry were all opposed, according to several accounts. They wanted to leave beverage can disposal in the hands of consumers, not the industry. Although Bill Coors encountered resistance from a skeptical industry, he pressed forward anyway and eventually gained acceptance. That year, the industry journal "Modern Metals" recognized Bill Coors as Man of the Year in the light metals industry.

- Coors had equipment shipped from Europe. Despite the controversy, Coors moved ahead with the aluminum can project to benefit both beer drinkers and the environment. In the mid-1950s, a small team made another trip to Europe to research and procure equipment to ship back to the Coors brewery in Golden.

- The Adolph Coors Co. debuted the two-piece aluminum can on Jan. 22, 1959. The original aluminum can was 7 ounces because a smaller can was easier to develop and gauge consumer reaction before scaling up to larger cans. (The first aluminum beer can debuted in 1958 by the now-defunct Hawaii Brewing Co., but structural issues, including inadequate lining, led to it being pulled from the market, according to multiple accounts.)

- The company was not in it for the money. Although the two-piece aluminum can took five years and $10 million to develop, Bill Coors encouraged other beverage makers to embrace the recyclable can and its prospect of reducing waste and harm to the environment.

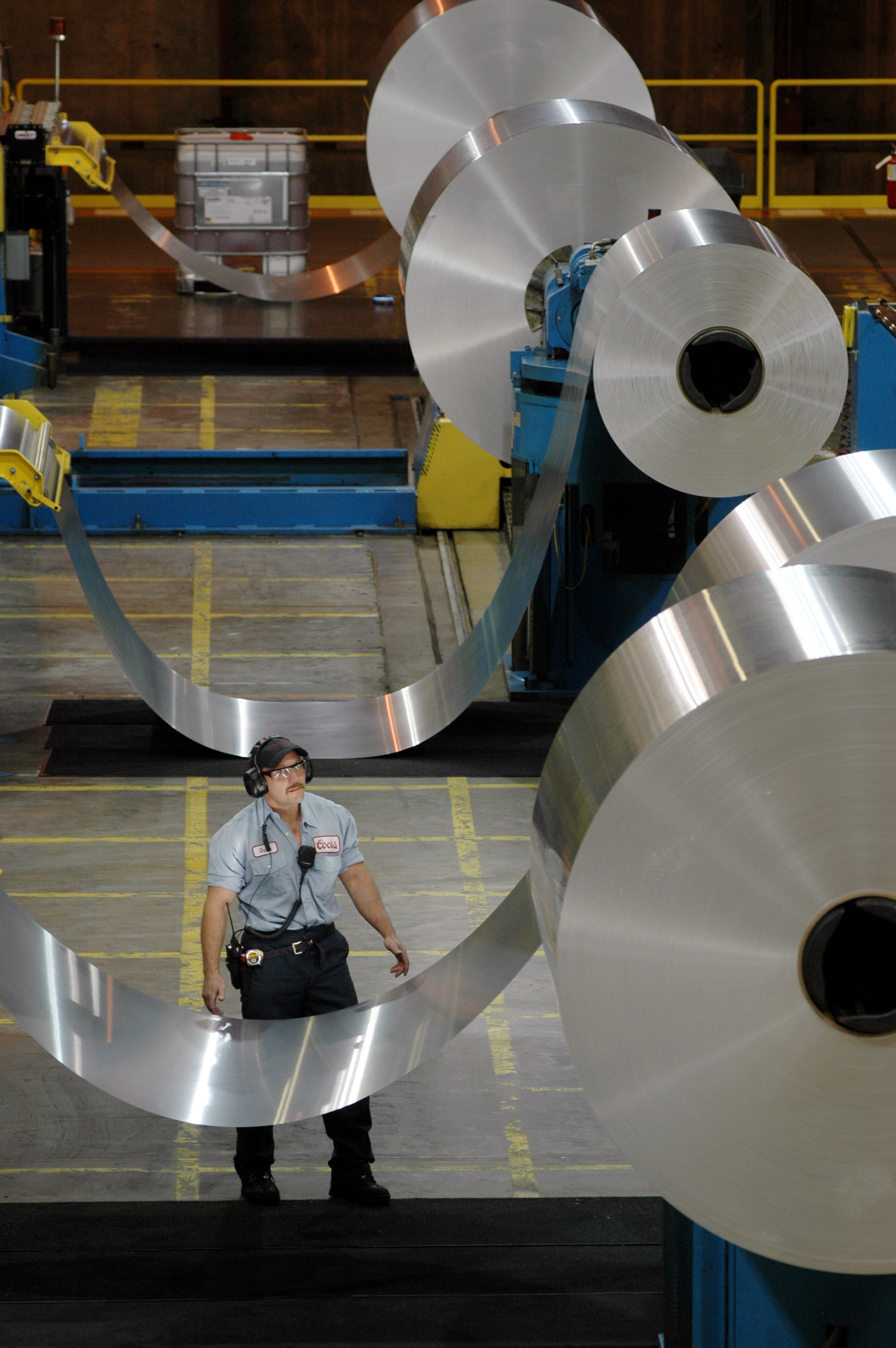

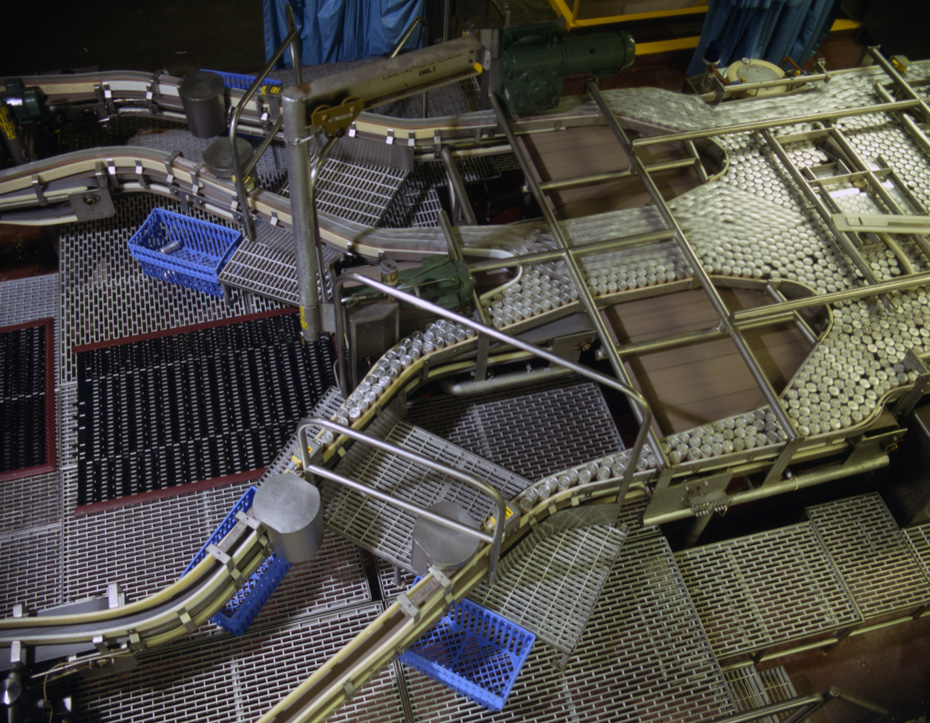

- Coors built its own can manufacturing plant in 1965. Consumers loved the aluminum cans — beer tasted better and stayed colder. Demand was such that supply couldn’t keep up. Coors needed more cans than could be manufactured at Coors Porcelain. So it built its own plant, becoming the first beverage company to produce its own cans. MillerCoors continues to manufacture cans today at Rocky Mountain Metal Container in Golden, Colo.

- Cash for Cans kicked off aluminum recycling efforts in the 1970. A distributor-led program netted consumers a penny a can and kicked off the first wide-scale aluminum recycling in the country. Through these recycling efforts, Coors started producing aluminum products such as calendars, ashtrays and tap handles.

- The steel can was put to rest in 1971. Thanks to the popularity of the aluminum can, Coors discontinued the use of steel cans on Nov. 12, 1971.

- MillerCoors Rocky Mountain Metal Container typically produces 13 million cans per day. Not only does the plant make 13 million cans a day, on average, but they go directly to the Golden brewery and are filled and shipped the same day.

Staff archivist Heidi Harris contributed.

*Some details from Beth Mende Conny’s A Catalyst for Change: The Pioneering of the Aluminum Can, a 1990 publication of the Adolph Coors Company.